Cross-section polishing

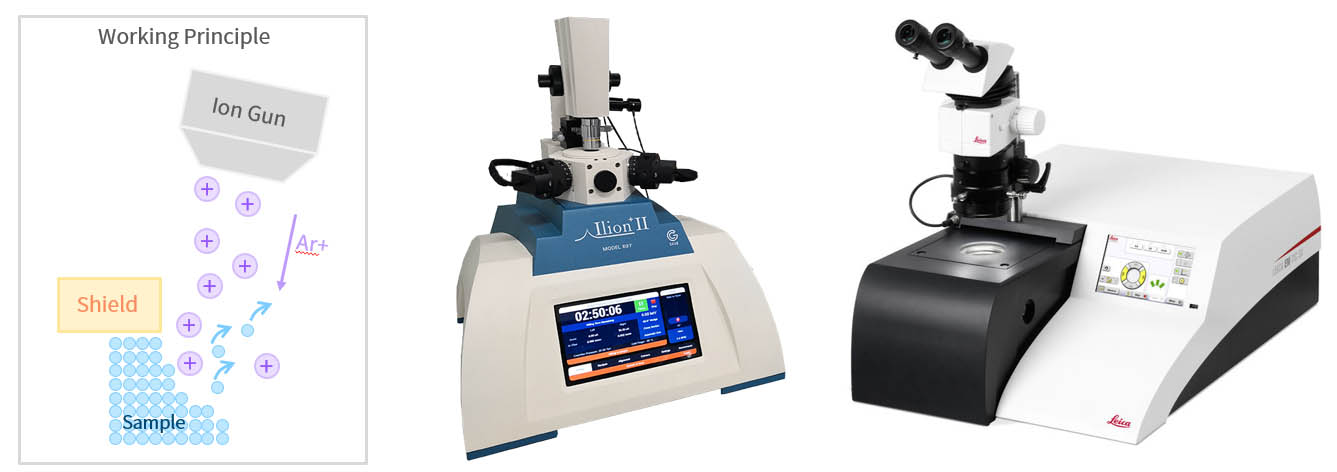

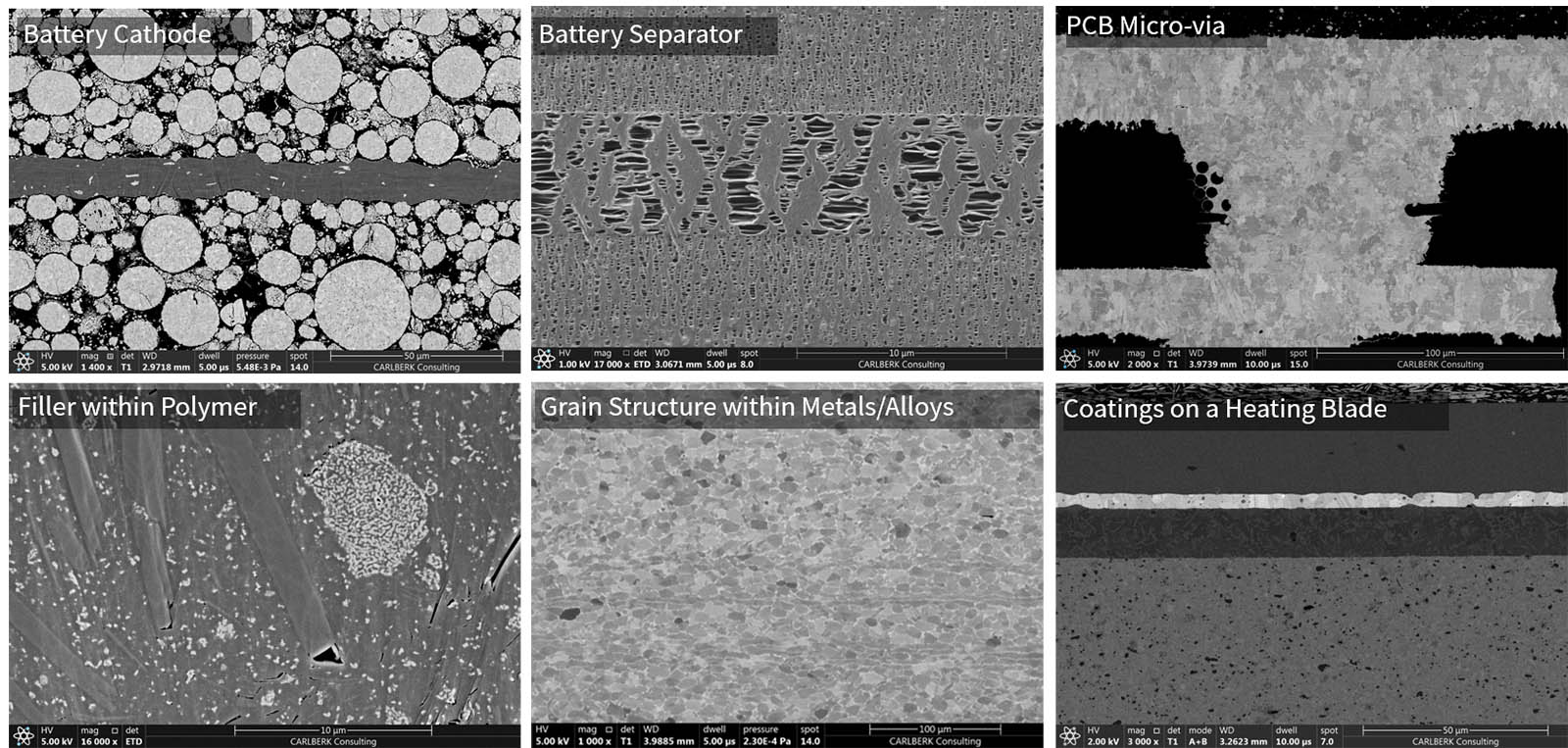

Cross-section polishing (CP) system utilizes broad argon ion beam (~1 mm) to mill away any materials that are not masked by the shield. It could produce a flat, smear-free cross sections readily be analyzed by SEM and electron backscattered diffraction (EBSD). The system is also equipped with cryogenic stage for preparation of temperature/beam sensitive samples. The cryo-stage is extremely useful for structural analysis of battery separators - cross-sectioning through ion milling at cryogenic temperature allows visualization of pore distribution without closing of pores due to local overheating.