Printed Circuit Board Assembly (PCBA) and Interconnect Technology

Electronic devices are used virtually everywhere, and printed circuit board assemblies (PCBAs) and associated components and interconnects are core of most electronic devices. Various factors, such as including component defect, materials issue, improper manufacturing, environmental factors, and even ageing, may wreak havoc on PCBAs and cause complete or intermittent failure.

CarlBerk has strong expertise and extensive experience in failure analysis and quality evaluation related to PCBAs. We provide systematic analysis utilizing both non-destructive and destructive in a logic pattern to help clients investigate why a PCBA failed. Depending on the failure mechanism determined by the investigation, we further work with client to ensure necessary corrective actions could be initiated to prevent re-occurrence of the failure and improve the overall product reliability. We have successfully supported analysis in the following area(s):

- Component failure (resistor, capacitor, diodes, MOSFET, etc.).

- PCB solderability evaluation and surface finish analysis.

- Solder joint reliability upon mechanical loading (mechanical shock, board flexing, shearing), thermal cycling, corrosion, and chemical attack.

- Conformal coating evaluation.

- Plated-through holes (PTH) and micro-via defect.

- PCB warpage issue.

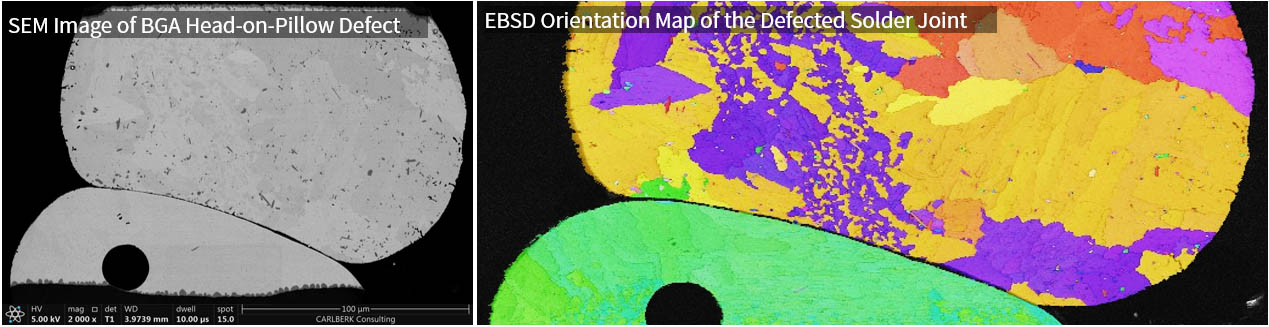

Example 1: BGA Head-in-Pillow SMT Defect

Head-in-Pillow (HIP) is one of the well-known defects in electronics manufacturing industry especially on the BGAs or CSPs that have been converted to lead-free alloys. The indication of this defect is non-coalescence (Non-wetting) of the entire solder joint between the BGA or CSP solder ball and the solder paste during reflow process. Without the formation of a unitary solder bump, even though the solder joint might still maintain electrical integrity, it poses a high risk of failure under mechanical or thermal stress during handling/usage.

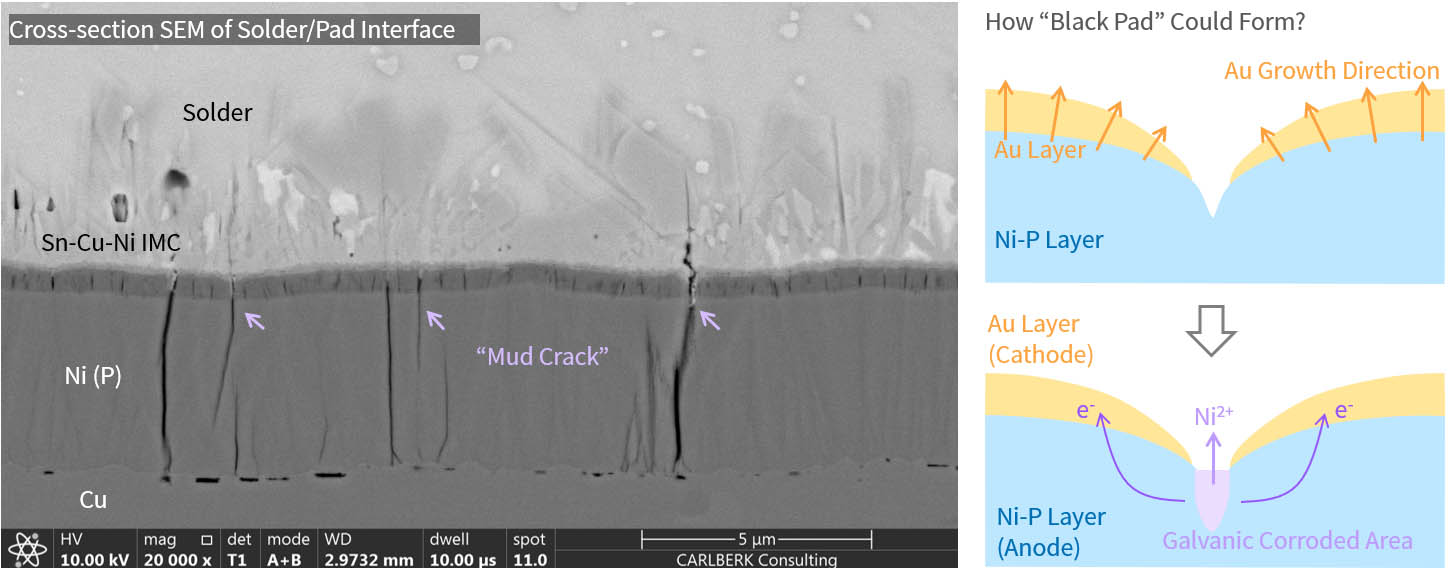

Example 2: ”Black-Pad” Defect

“Black pad” is a common defect observed on PCB pad finished by electroless nickel – immersion gold (ENIG) surface finish, which might result in reduced solderability and susceptibility to solder brittle fracture. “Black pad” is generally believed to be caused by corrosion of electroless nickel at the nickel nodule boundaries, which could hardly be detected by normal quality control as immersion gold layer masks the underlying nickel surface.