What We Offer

Failure Analysis

The goal of failure analysis to provide answers on why a product or component has failed and how to prevent failures in the future. At CarlBerk, we work closely with client to track down the weak link in the chain of design-manufacturing-performance that’s causing the failure and place high emphasis on delivery of effective, feasible solutions.

>> Click to Learn More

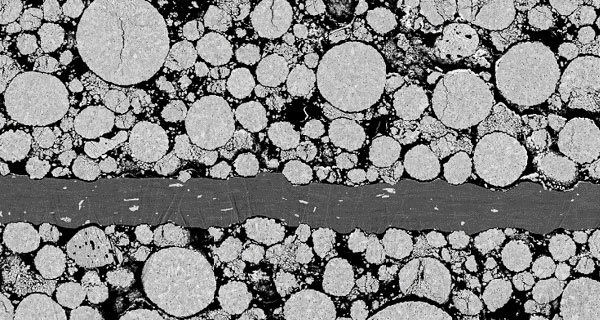

Materials Testing and Characterization

CarlBerk maintains a capability of characterizing both organic and inorganic materials by multiple microscopic and spectroscopic tools in our in-house laboratory. We also developed packages of proprietary analysis protocols through collaboration with research institute and instrument manufacturers, allowing us to perform customized analysis that is not otherwise commercially available.

>> Click to Learn More

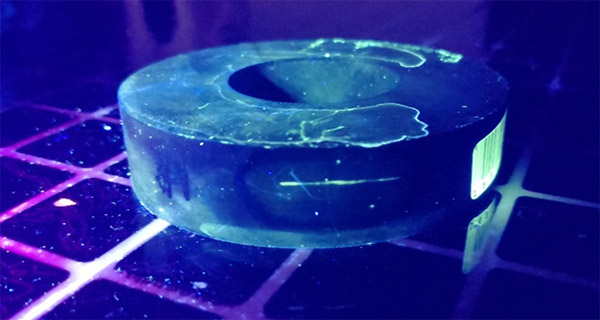

Quality Evaluation and Vendor Comparison

CarlBerk also assist our client in their quality control activity by offering high standard quality evaluation of the material, component or prototype before the large-scale production. Our failure analysis experience allows us to better relate the experimental results with product’s specific requirement and advise on preventing potential failure at early stage.

>> Click to Learn More

Factory Audit & Training

CarlBerk provides informative production line audit service for clients who would like to ensure good manufacturing procedures was being implemented on factory floor. In addition, CarlBerk also offer training on a wide variety of topics including SMT, metallurgy, materials characterization, polymeric materials as well as basic failure analysis methods.

>> Click to Learn More