In-situ Mechanical Testing

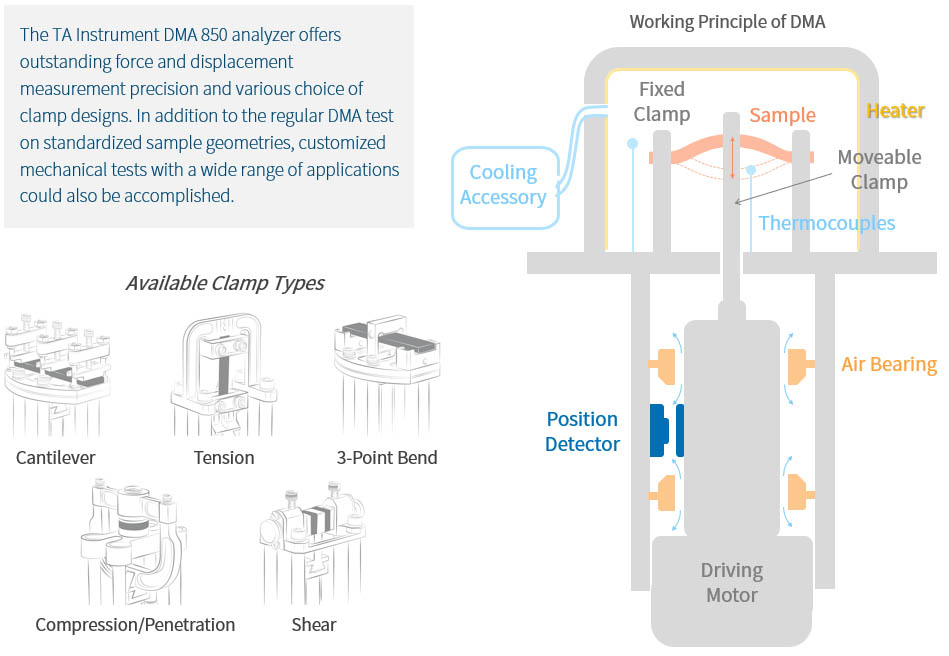

Mechanical testing are useful for evaluating materials’ response to mechanical loading. However, regular mechanical testing usually required sample to be machined to standard size and shape, posing difficulties for sample preparation from real product component (especially when limited amount of sample is available). Also, results from standard testing might fail to represent the materials true response at actual usage scenario.

At CarlBerk, we do not let our service limited by established testing standards and known procedures. We constantly develop new test gigs, fixtures, and experimental protocols through collaboration with research institute and instrument manufacturers, allowing us to perform customized analysis that is not otherwise commercially available.

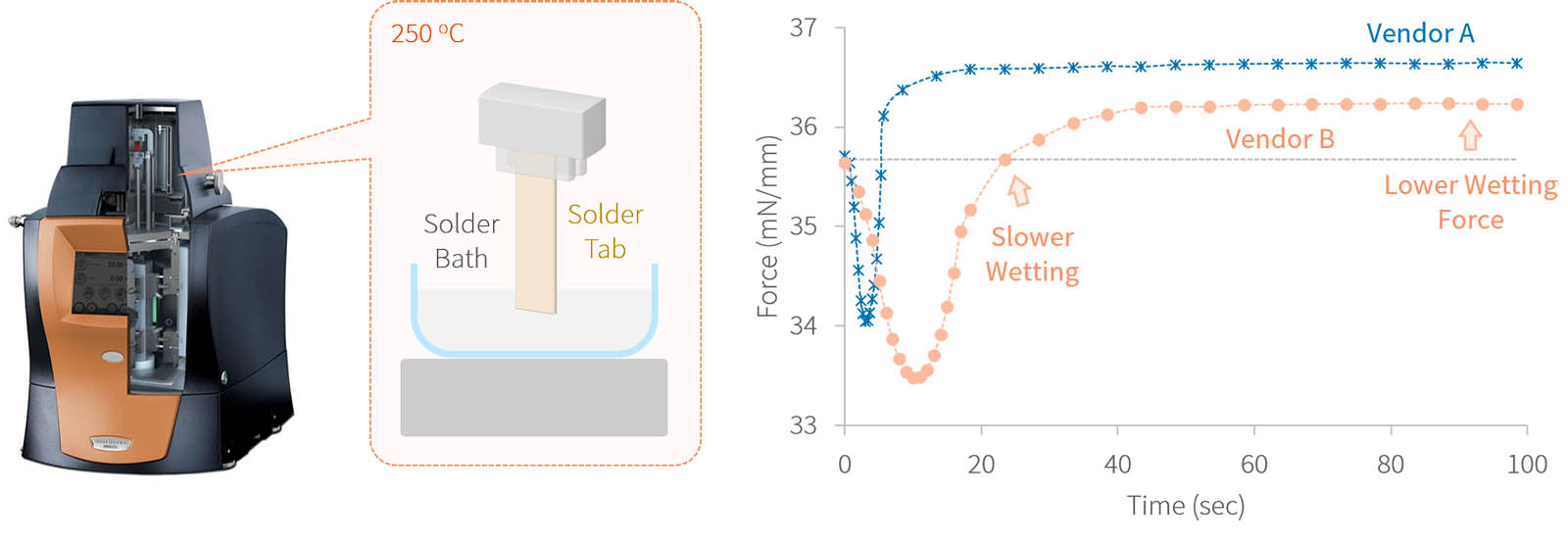

Example 1: Customized Wetting-Balance Test for Solderability Assessment

Solderability is defined as the ability of a metal to be wetted by molten solder and it is typically evaluated through wetting balance test. However, regular wetting-balance testing require large amount of solder and specific sample size that might not be feasible for small sized solder pad/tab. Here we developed a customize wetting-balance test by utilizing our in-house DMA. Through this method, we successfully show the difference wetting behavior of solder tabs sourced from two vendors – tabs made by vendor B exhibited slower wetting and lower wetting force than that from vendor A.

Example 2: In-situ Monitor Dimensional Change of a Cylindrical Cell during Cycling

Here we demonstrated a customized test for in-situ monitor dimensional change of a cylindrical cell during cycling. Based on the measurement, we estimated the internal pressure of fully charged cylindrical cell using finite-element analysis (FEA) and evaluated the potential risk of rapid self-discharge due to local high-pressure point on separator.