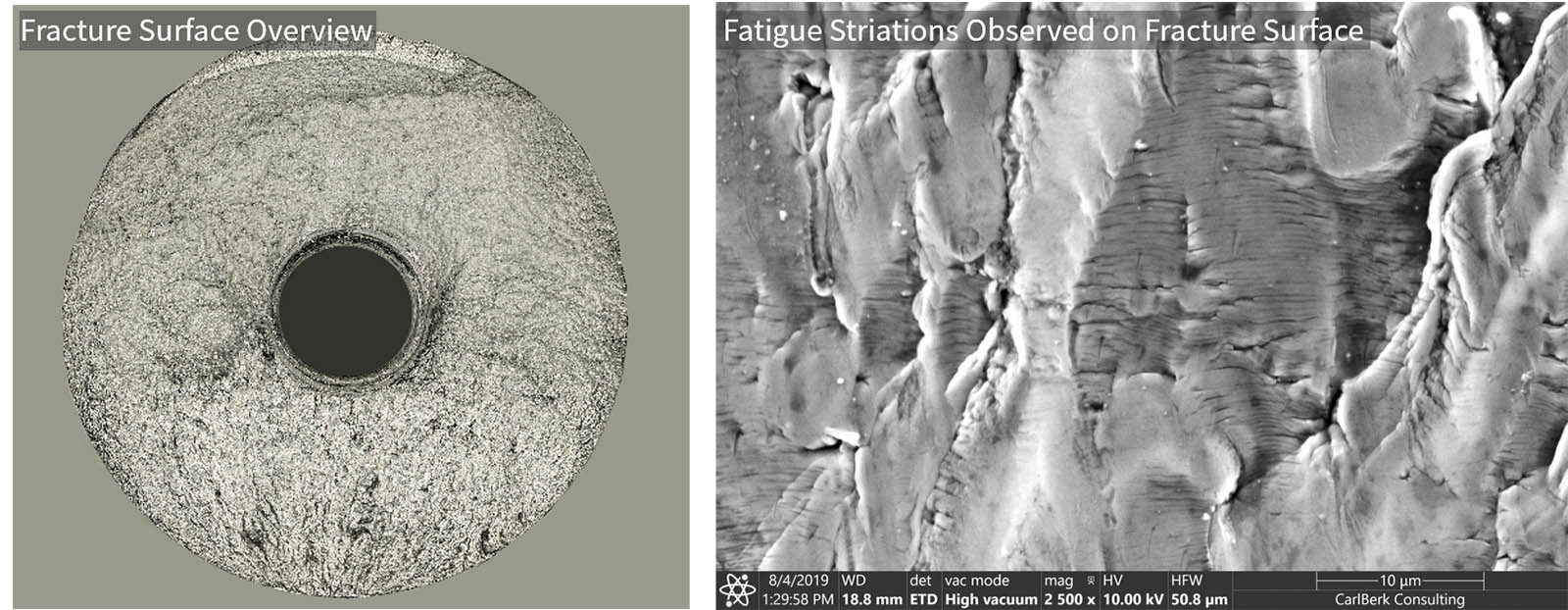

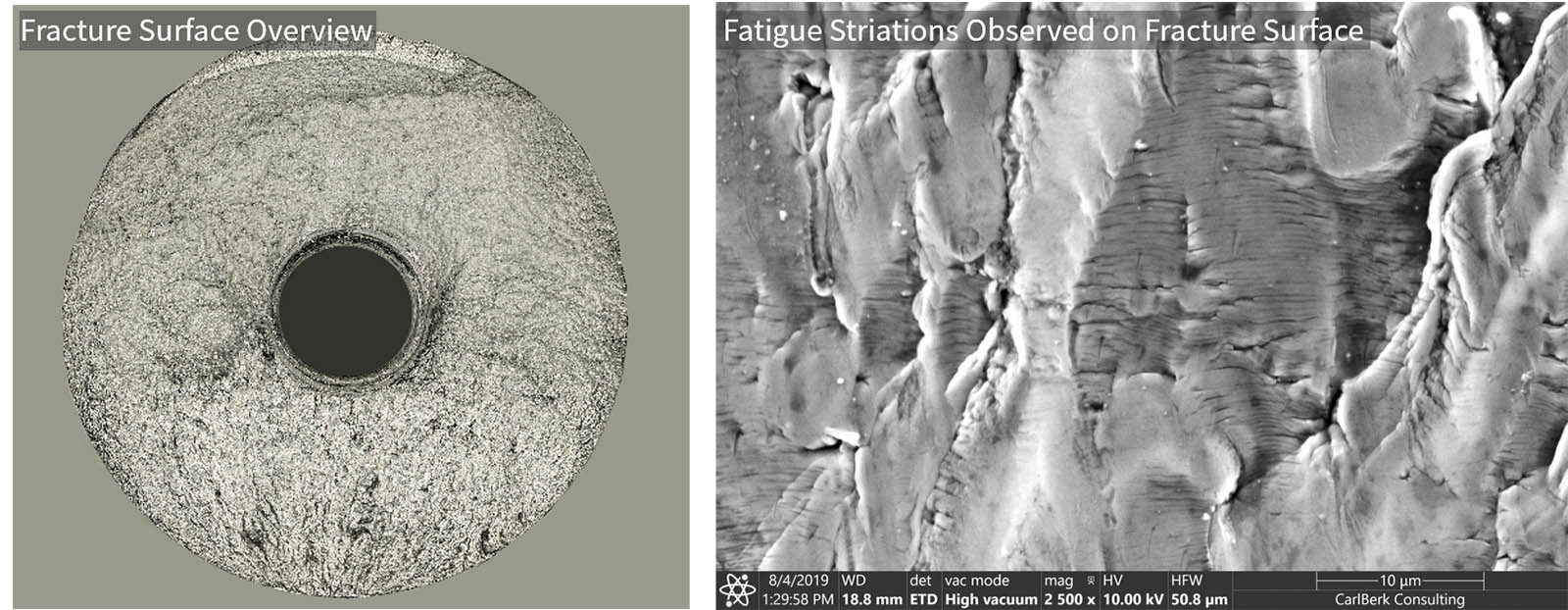

Example 1: Fractography Analysis of a Metal Part from a Scooter

The Scooter structural component (made of aluminum-based alloys) failed due to a pre-market road test. The fracture surface suggested a failure due to fatigue.

Technology has always been a risky business - no matter what the technology is, our best estimates of their success tend to be too optimistic, and products and components do fail due to various causes. The goal of failure analysis (FA) is to provide answers on why a product or component has failed and how to prevent failures in the future.

At CarlBerk, we provide failure analysis service in line with client’s essential needs. We work closely with our client to track down the weak link in the chain of design-manufacturing-performance that’s causing the failure. Unlike regular 3rd party testing lab, we provide packaged service that including experimental analysis, data interpretation, and technical discussion, and highly emphasize on delivery of effective, feasible solutions. Benefited from highly efficient team and in-house analytical laboratory, our initial findings could be communicated to client in short turn-around and greatly reduced the loss from waiting. So far, we have successfully solved hundreds of FA cases for clients from various technical fields. Some of our key areas of support include (but not limited to):

The Scooter structural component (made of aluminum-based alloys) failed due to a pre-market road test. The fracture surface suggested a failure due to fatigue.

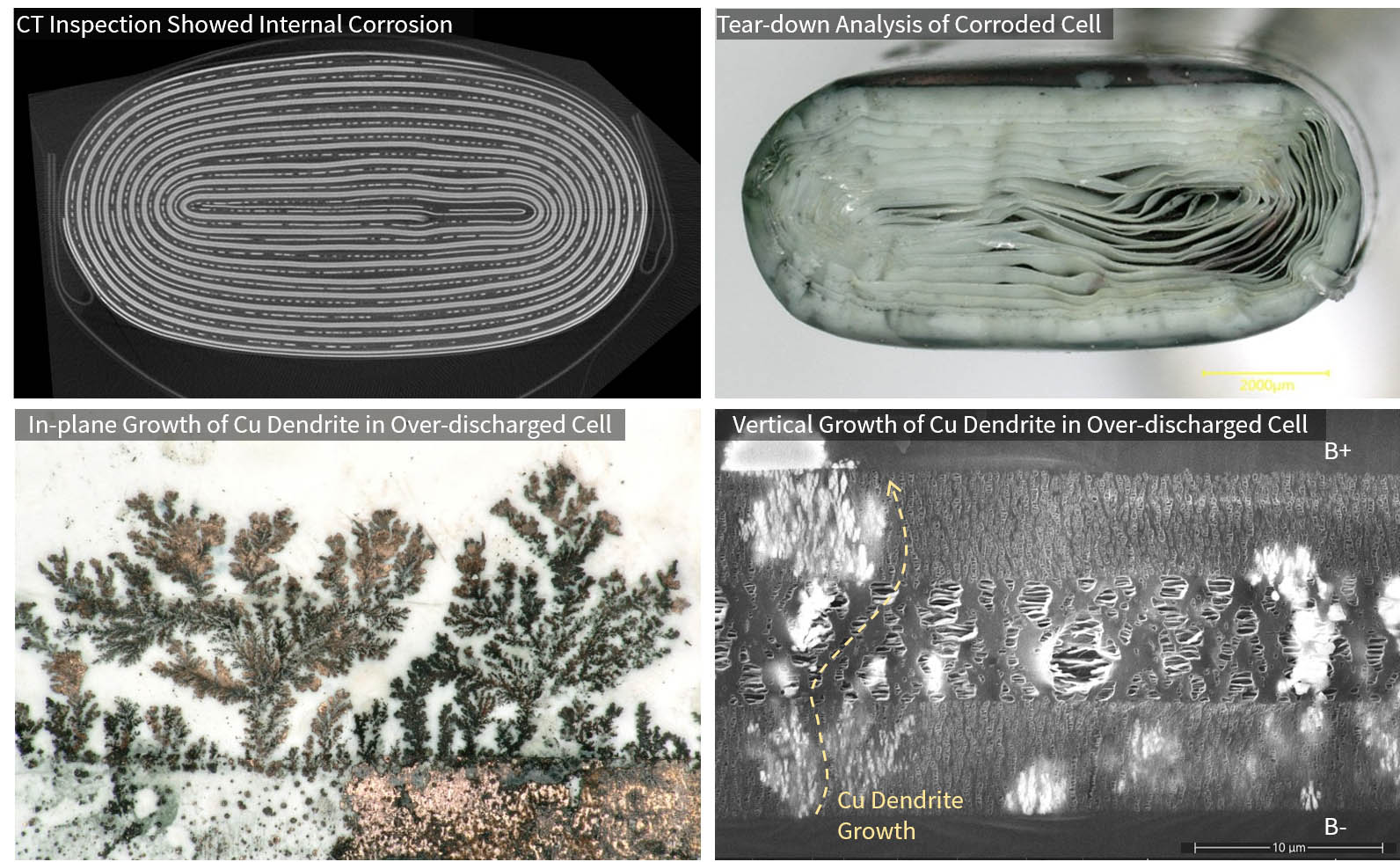

Excessive internal corrosion and Cu current collector dissolution occurred as a result of cell over-discharge. The dissolved Cu re-deposited as Cu dendrite during subsequent charging and finally penetrated the separator.

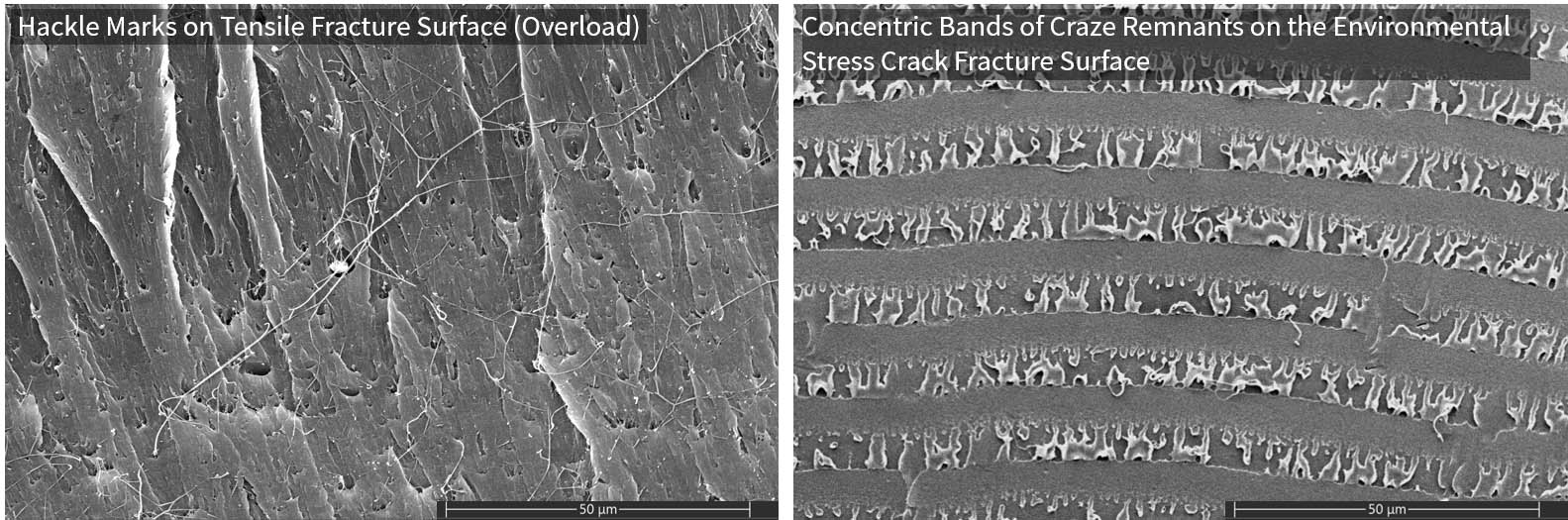

A fracture surface not only tells the origin of failure, but also reveals the type of loading that causing the failure. For engineering plastic like polycarbonate, fracture surface created by different loading condition could exhibit drastically different microstructural features.

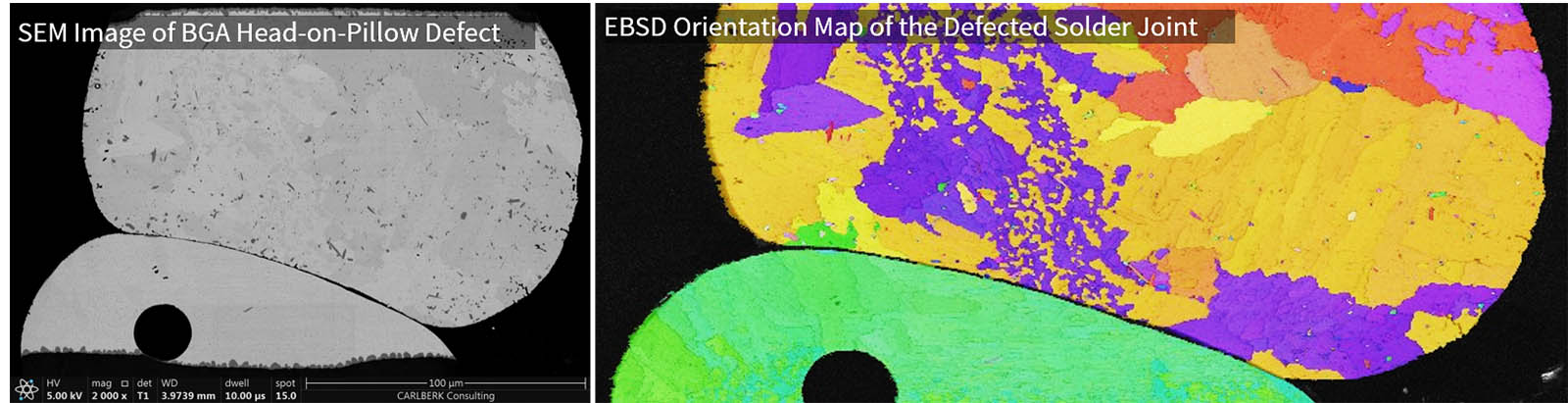

Head-in-Pillow (HIP) is one of the well-known defects in electronics manufacturing industry especially on the BGAs or CSPs that have been converted to lead-free alloys. The indication of this defect is non-coalescence (Non-wetting) of the entire solder joint between the BGA or CSP solder ball and the solder paste during reflow process. Without the formation of a unitary solder bump, even though the solder joint might still maintain electrical integrity, it poses a high risk of failure under mechanical or thermal stress during handling/usage.